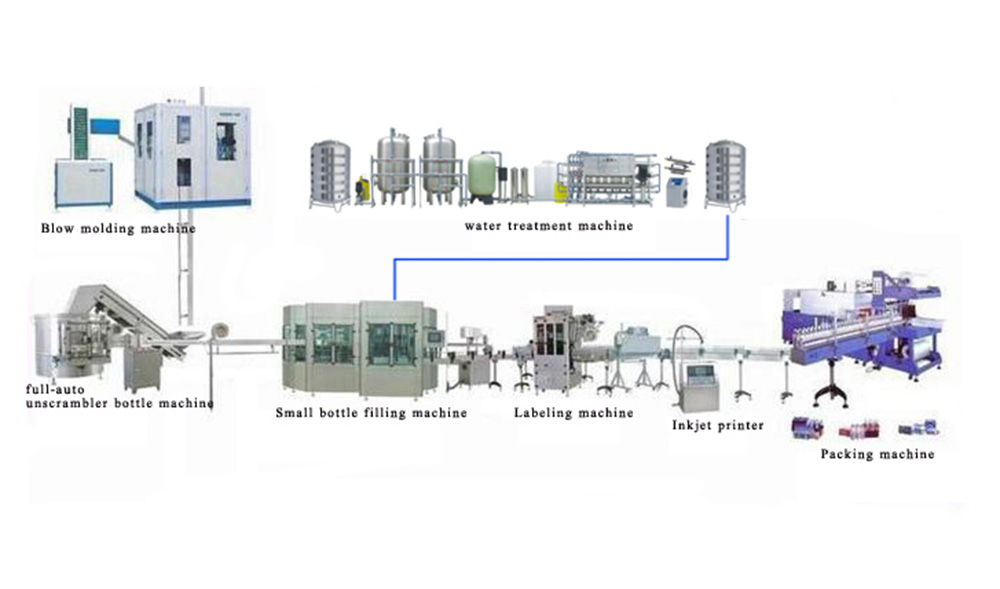

4000-6000 BPH Fully Automatic Line

Automatic Bottled Water Production Line

(Output:4000-6000B/H based on 500ml bottle)

Equipment List

| Equipment | Mole | Qty | Remark |

| Bottle Washing-Filling-Capping 3 In 1 Machine | CFG 18-18-6 | 1 | 4m air conveyer and 3mdouble chain belt conveyer

Automatic cap feeding machine |

| Full automatic blow molding machine | HY-6000 | 1 | Automatic preform feeding

1.2M3/30kg high pressure compressor 4 sets 2.3M3/10kg low pressure compressor 1 set 3HP water cooler and 3.0M3/30kg air cool drier 1.3M3/20kg air tank Blowing mould one set(between 300ml-2L) |

| Automatic Sleeve Labeling Machine | ZX-150B | 1 | 7M conveyer belt

Heat shrinking oven and steam generator |

| Small Cheater Ink Jet Printer | WDD 43S plus | 1 | Auto-cleaning nozzle function

With 4 boxes ink + 20 boxes solvent(1 year) |

| Auto Shrink- Wrapping Packing Machine | JMB-250A | 1 | 2.5M conveyer

Independent electric box with PLC and tough screen |

| Sub total | Complete Production Line | 6 | Our standard voltage level is Three phase/380V/50HZ |

Optional Part:

| Equipment | Mole | Qty | Remark |

| Automatic Bottle Unscrambler | LP-12 | 1 | Capacity: 6000BPH |

II Specification for each Item

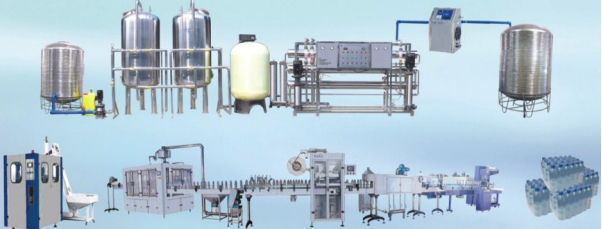

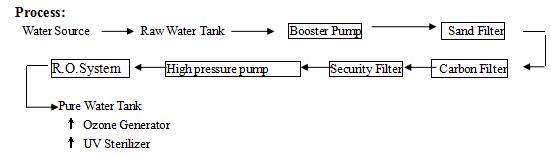

Part One: R.O. Water Purification System (Model: RO1000I (4000L/H))

Design basis and treated water standard:

1 Produced water’s application: Bottle drinking water

2 The capacity of produced water: 4000L /H

3 System Configuration: Pretreatment + One Stage Reverse Osmosis Desalination System.

4 Designed recovery: 50-65%.

5 Rejection rate:≥ 97%

6 Voltage: 3 phases, 380V, 50Hz; Power: 7 KW (Can be customized at your country’s voltage, please tell us about it when ordering)

Part Two: Washing-Filling-Capping 3 in 1 Machine (Model: XFG18/18/6)

Automatic machine for bottle washing filling and capping, with 18 washing chucks, 18 filling valve and 6 capping heads, production capacity for 500ml mineral water is 4000-6000 bottles per hour. The available bottle sizes for this machine are 300ml – 2000ml.

Main Technical Parameters:

Capacity: 4000-6000bottles/hour (500ml)

Bottle DiameterΦ50~95mm

Bottle height: 150~320mm

Cap specification: Standard plastic rib caps

Bottle washing pressure: 0.18~0.25Mpa

Water consumption of bottle washing: 1200kg/h (can be adjusted)

Spraying working position: 10

Gas source pressure : 0.4Mpa

Air consumption: 0.5m3/min

Total Power: 8.63KW

Weight: 3000Kg

Overall Size: 2450×1800×2200(mm)

Main components of this machine

| 3 in 1 washing filling and capping machine | 1 |

| Cap dosing system | 1 |

| Air Conveying System | 4 meters |

| Belt conveying system | 3 meters |

Pictures: (Only for reference)

Part Three: HY-6000 Fully Automatic Bottle Blow Molding Machine

Equipment list :

|

HY-6000 (6cavity)

|

Model | Product name | QTY |

| HY-6000 | Main machine | 1SET | |

| HY-6000 | Auto-loader machine | 1 SET | |

| 4.8m³/30Bar | High pressure compressor | 1SET | |

| 2.1m³/12.5Bar | Low pressure compressor | 1SET | |

| 3HP | Water chiller | 1 SET | |

| 4.0m³/30Bar | Air cold dryer | 1 SET | |

| 2.0 m³/30 Bar | Air filter | 4 SETS | |

| 0.6 m³/30Ba | Air tank | 1 SET | |

| 6 cavity | Bottle mold (Aluminum) | 1 SET |

DESCRIPTION :

HY-6000 is the fastest liner blow molding machine in mainland of China by now. HY-6000 reaches around 4500BPH for 1500ML bottle. Its baking tunnel is separated from the blow station so that time for mold opening is shortened with a result of speedy blowing and high output, damage to machine is lessened so as to keep reliable performance and prolong service life, as well as machine runs more smoothly and steadily.

HY-6000 is controlled by PLC. The whole process from preform feeding to bottle discharging is completed automatically with advantages of labor saving and no pollution. HY-6000 consists of three main parts: preform loading system, Heater channel & blow station.

MACHINE FEATURES:

1. Machine use of advanced PLC control system , stable in performance, automatic preform feeding .

2. Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the rails simultaneously in the infrared preheater

3. High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the reflecting board in the preheating area, and eternal temperature in the preheater with an automatic thermostatic apparatus.

4. High safeties with security automatic-locking apparatus in each mechanical action, which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

5. No contamination and low noise with the air cylinder to drive the action instead of the oil

pump.

6. Air route design is divide into two parts ,

7. Ideal effect of the chilling with the chilling system

8. Low rejection rate: less than 0.3percent

| Container | Max Volume | L | 2 |

| Max Neck Diameter | mm | 38 | |

| Max Container Diameter | mm | 105 | |

| Max Container Diameter | mm | 335 | |

| Cavity | 6 | ||

| Theoretical Output | bph | 5000(*) | |

| Electrical | Total Power | KW | 47 |

| Heating Power | KW | 44 | |

| Max Heating Power | KW | 60 | |

| Air Compressor | Operating Pressure | Mpa | 0.7 |

| Low Pressure Consuming | L/min | 1400 | |

| Blowing Pressure | Mpa | 3.5 | |

| High Pressure Consuming | L/min | 3000-5000(**) | |

| Chiller | Pressure | Mpa | 0.3-0.5 |

| Temperature | ℃ | 10-12 | |

| Flow Rate | L/min | 30 | |

| Machine | Machine Size | m | 4.8x2.3x2.03 |

| Machine Weight | Kg | 4500 | |

| (**)Depending on bottle size, shape and weight.

(*)Depending on bottle size and operation conditions. |

|||

Part Four: Automatic Sleeve Labeling Machine ZX-150B

The machine is consists of three parts: Main machine, Steam heating shrinking oven and steam generator.

This serial of equipments serves in full auto smart packaging line integrating the functions of delivering bottles, classifying bottles, label sleeving and label shrinking. High speed, precise positioning, saving labor and perfect package are the design tenet of this serial of equipments.

Component List

| Sequence | Product Name | Amount | Unit |

| 1 | ZX-150B Type Trapping Label Machine | 1 | set |

| 2 | ZX-2000 Steam Heating Shrinking Oven | 1 | set |

| 3 | ZX-18KW Steam Generator | 1 | set |

| 4 | Conveyor | 7 | meter |

Technical Parameters:

1. ZX-150B Technical Parameters:

| Input Power | 3.0KW |

| Input Voltage | Single phase/220V AC |

| Production Efficiency | 150 bottles/min |

| Size of Host Machine | 2100L×850W×2000H |

| Applicable Diameter of Bottle Body | 35mm~95mm |

| Applicable Length of Label | 30mm~250mm |

| Applicable Thickness of Label | 0.03mm~0.13mm |

2. ZX-2000 Steam Heating Shrinking Oven

| Input Power Supply of Blower | 1, 220VAC 0.75KW |

| Input Power Supply of Steam Generator | 380V/50HZ |

| Working Pressure | ≤0.1Mpa |

| Weight | 230Kg |

| Steam Consumption | 10-20Kg/h |

| Size of Oven Body | 1800L×400W×450H |

| Transporting Speed | 0-35m/min |

3. ZX-18KW Steam Generator

Input power of heater: 18KW

Voltage: 380V

Air pressure :0.4~0.7Mpa

Steam volume :3.8~22.8kg/h

Water Container Volume :28L

Dimension:630*560*1360(mm/mm/mm)

Part Five: Small Charter Ink Jet Printer (Model: WDD 43S plus)

Advanced performance

Unique ink viscosity and liquid level detection technique guarantees the superior printing of high clarity, but also allows for the higher suitability to anti-mobility ink and yellow ink than like inkjet printers.

The dissectible nozzle completely overcomes nozzle clogging that has constantly existed in the industry, thus significantly reducing the use cost of users.

Magnetically controlled non-contact high voltage switch successfully prevents the machine malfunction caused by the poor contact after a long time of running.

Specially upgraded double electric eye triggered printing, variable database information transmission, round-trip jet printing and up to 50000 times repeat print technological function, enable the machine meet more application demands.

Transit and switch off of high voltage controlled by particular software completely avoid the hardware malfunction caused by all the switch design.

The circuit system and ink system is separated to avoid the accidental damage to the printer in maintenance and use.

Drawer type ink system makes the maintenance more convenient.

It is easier to judge and find the machine fault and prevent unnecessary maintenance expenses by directly controlling the close/open of any valves and pumps in the ink system separately via the menu.

Line speed capability

Max number of lines of text up to 4

Max line speed up to 210 m/min (Based upon single line, 10 character per inch)

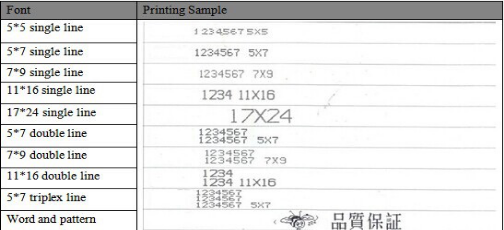

Font matrix configuration

Single-line: 5×5, 5×7, 7×9, 9×12, 11×16, 17×24

Twin-line: 5×5, 5×7, 7×9, 9×12, 11×16

Tri-line: 5×5, 5×7, 7×9

Quad-line: 5×5, 5×7

Nominal character height

Selectable from 2mm to 18mm depending on font

Throw distance

Optimal: 10mm

Range: 5mm-15mm

WDD 43S plus Standard printing performance

Detail Pictures of the machine:

Part Six: Auto Shrink- Wrapping Packing Machine (Model : JMB-250A)

Scope of Application:

Auto shrink- wrapping machine series are suitable for the package of bottled water ,beverage、household、 electric appliances、electrical units、floor boards、pottery and so on.

Feature:

* It can make package perfect whatever it is without pallet, cartoon, rectangle, round or flat shape.

* It has the advantage of less cost and better appearance. It applies PLC automatic controller, man-machine interface, ensure that no fallen bottle, no bottle shortage.

* Replace film conveniently. It has failure alarm, lock device, reliable running.

* The whole machine applies super steel and stainless steel, with compact and endurable structure. * This new type of wrapping machine is the ideal equipment for beverage filling line.

Technical Diameter:

Technical Diameter:

| Machine Dimension | 5050*3300*2100(L*W*H.mm) |

| Max packed size | 600*400*350(L*W*H.mm) |

| Shrinkage film material | PE,PVC,POF. |

| Shrinkage film thickness | 0.03-0.15(mm) |

| Oven temperature | 160 – 260° |

| Max output | 6-12Bag/Min. |

| Actual Power | 15Kw/H. |

| Voltage | 380V,3Phs |

| Weight | 1.2T. |

| Applicable Internal Diameter of Paper Tube | 5″~10″. |

Packing Type:

a)300-600ml:Big package: 4×6,4×5;Small package: 3×4,3×5.

b) 700-2000ml:Big package: 3×3,3×4;Small package: 2×2,2×3.

Optional Machine:

Automatic Bottle Unscrambler model: LP-12

LP-12 Series bottle unscrambler is the necessary matching products of high speed bottle filling equipments, with the mechanical actions to tidy the messy bottle orderly to the air conveying system of the filling machine. It can satisfy the requirement of full automatic bottle water production line.

1. Main features:

1) Torque Limit component is applied in the reducer of the main motor, in order to avoid damage of the machine when some problems happen.

2) Applied double bottle tidying process to ensure that each working position with bottles in it and improve the production efficiency.

3) Applied bottle mouth hanging and air conveying system, in order to avoid bottle overturning while conveying.

4) With the function of broken bottles removing.

5) With bottle stuck detector, when the bottle get stuck, the machine will stop automatically and warning.

6) With bottle empty detector, which is used to send the working sign to the bottle lifter, then the lifter will replenish the bottle automatically.

7) You can control the start and stop of the bottle scrambler switch off button on the air conveyor.

8) With oil dosing mouth to add lubricating oil to the wheel gears, bearings and cams.

9) With maintenance door and mould changing door.

Main Parameter:

| Model | LP-16 |

| Capacity | 6000 bottles/hour (500ml) |

| Power of Main motor | 1.5KW |

| Power of bottle lifter | 0.75KW |

| Power of draught fan | 1.1KW |

| Request air pressure | 0.5-0.7Mpa |

| Dimension | 3500×2200×2300mm |

| Weight | 4000kg |