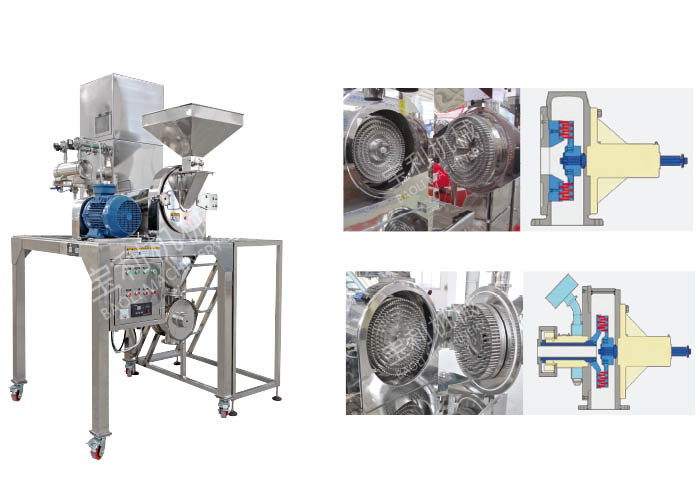

JB Series Pin-type Mill

Product Description

Working Method: Material is delivered from the hopper into the crushing cavity by screw conveyor.Between the impact / cutting / grinding of the high speed rotating cutter and the fixed cutter or the movable cutting tool,it is crushed.Then the powder discharge through the screen. Crushed size can be adjusted by changing the screen or adjusting the different rpm.

Main advantages: According to the international advanced grinding technology research and design, the structure is novel and reasonable, simple and compact, small size, high efficiency, beautiful appearance, easy to wear parts for easy replacement. Select the gap between the rotor and the stator, adjust the speed of the corresponding rotor speed, then make the grinding process in the best condition. The machine has a good sealing performance, built-in labyrinth seal, machine door with “0” type sealing ring, no dust leakage. The material space of the crushing chamber is large. Due to the speed of high-speed rotation, with a large amount of air, which has self cooling function, using partial crush thermal sensitive material. Bearing system adopts imported technology with long working time. The pipeline is connected with a quick dismantling type structure, which can be quickly and conveniently disassembled and assembled. Equipped with pulse type dust collector, no dust in the production process, the powder in the air bag can complement interception powder, exhaust emissions to meet the requirements of environmental protection and clean. Powder bag complement interception powder can effectively recycle, reduce material loss rate. This machine is suitable for brittle resilient materials, as well as dry or high moisture content of crystalline materials. Product fineness is less than 50μm, the fineness can be changed by adjusting the speed of the rotor or change the number and arrangement of needle sticks. Product technologies: Fineness range from 60 mesh to 200 mesh Fineness can be adjusted by the rotor speed and grinding tool selection Relative linear speed up to 150m / sec Can handle the different materials of Mohs hardness 2-3.5 Easy to operate, easy to clean The scope of application from the laboratory model to large-scale production models